Durable special materials which are resistant to fire cracking and heat

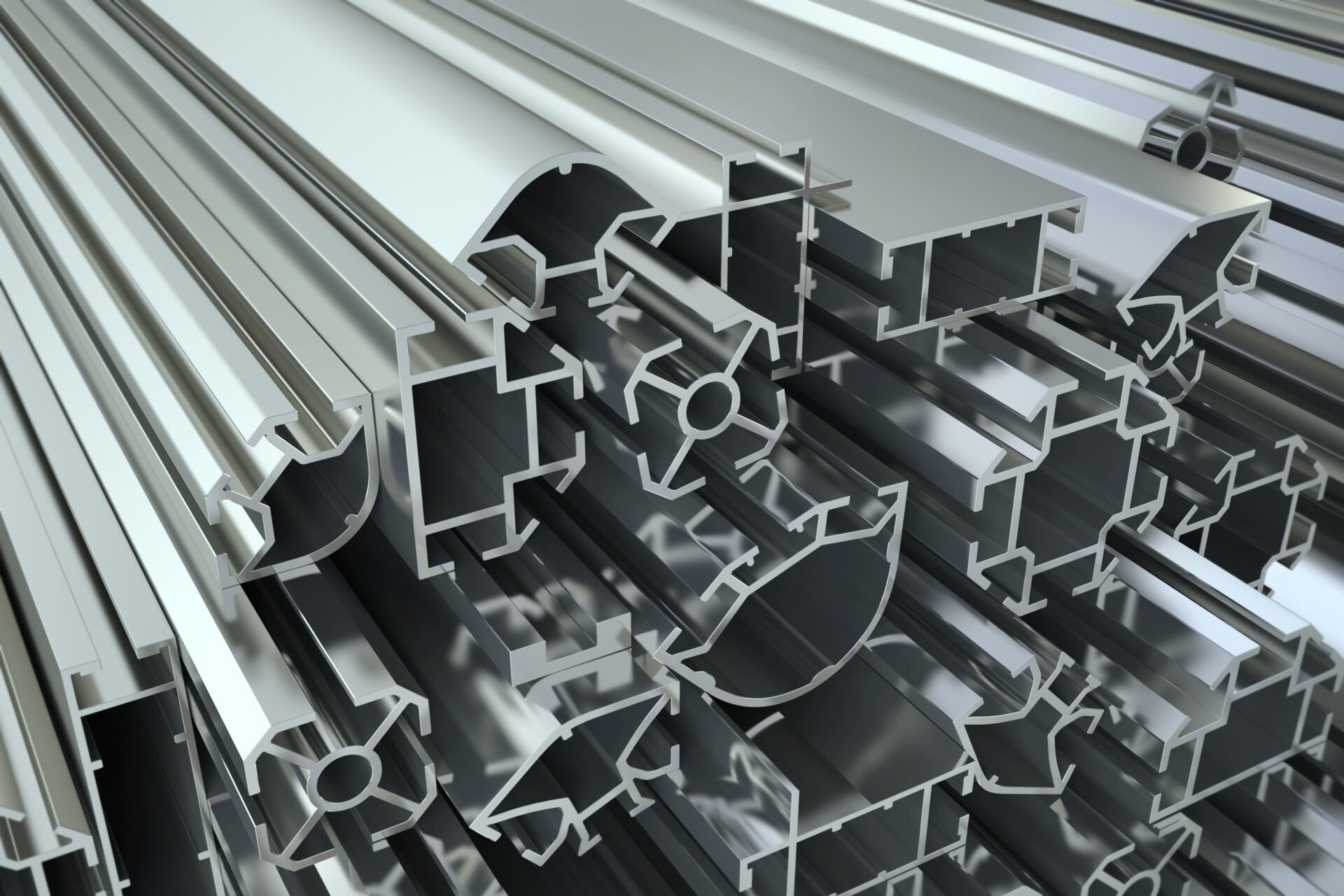

During extrusion, a metal blank heated to forming temperature is pressed through a die by a ram in a press cylinder. This results in a strand with a length of up to 60 m. This process places high mechanical and thermal requirements upon the extrusion components such as dies, inner bushings, rams and rupture disks.

These tools must therefore be made from special materials which offer high resistance against fire cracking, heat resistance and durability along with resistance to erosion and high-temperature corrosion.

List of special materials used in the extrusion industry

Material no.

Name

UNS no.

ASTM

VdTÜV

Other

Material type